Manufacture Heat Exchangers Faster Now!

In today’s rapidly evolving manufacturing landscape, speed and precision are more crucial than ever, especially in heat exchanger production. To stay competitive, you need advanced technology that accelerates production without compromising on quality.

Why Precision Matters in Heat Exchanger Manufacturing

Heat exchangers, essential in industries like HVAC, automotive, and power generation, rely heavily on the quality of fins and tubes for optimal performance. As the demand for more efficient and compact heat exchangers grows, the need for precise manufacturing becomes paramount. Errors in fin production, tube expansion, or tube bending can result in poor performance, increased energy consumption, and higher operational costs, making high-quality machinery an absolute necessity.

Advanced Fin Dies: Quality You Can Count On

Fins play a critical role in a heat exchanger’s efficiency. Our advanced fin press dies ensure each fin is crafted with exceptional precision, enhancing heat transfer capabilities and reducing energy waste. This results in high-performance, energy-efficient heat exchangers that consistently meet and exceed customer expectations.

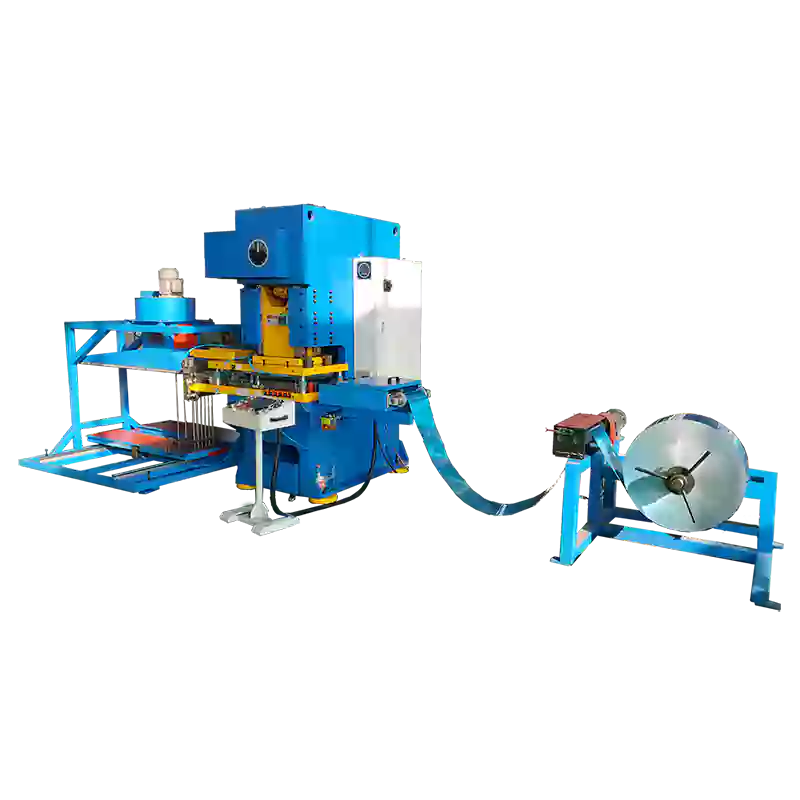

Efficient Fin Press Lines: High Quality at High Speed

While speed is essential, maintaining quality is equally important. Our fin press lines are designed to handle large volumes without sacrificing quality. These systems, including our fin press machines, are flexible enough to meet your specific needs, allowing you to scale your operations efficiently while maintaining the highest standards of production quality.

Vertical Expansion Machines: Maximize Space and Power

Space efficiency is a major concern in manufacturing. Our vertical expansion machines are designed to maximize space utilization by expanding tubes perfectly within heat exchanger assemblies. These machines save valuable floor space and integrate seamlessly into existing production lines, boosting both productivity and efficiency.

Fully Automated Tube Bending: Quick and Accurate

Tube bending is a critical step in the production of heat exchangers. Our fully automated tube bending systems ensure that each tube is bent to precise specifications, enhancing both speed and product quality. This level of automation minimizes the risk of product failure and maximizes system reliability, making it an invaluable asset to your production line.

Why Work with Us?

- Precision: Our machines, including the fin press and fin press lines, are engineered to deliver exact, consistent results every time.

- Efficiency: Accelerate your production processes without compromising on quality.

- Scalability: Seamlessly grow your operations with our flexible, adaptable equipment.

- Cost Savings: Reduce waste and improve operational efficiency, leading to significant cost savings.

- Future-Proof Technology: Stay ahead of the curve with equipment that evolves alongside your business needs.